The Rising Cost of Metal Theft: Why Plastic Downspouts Are the Secure Choice

Share

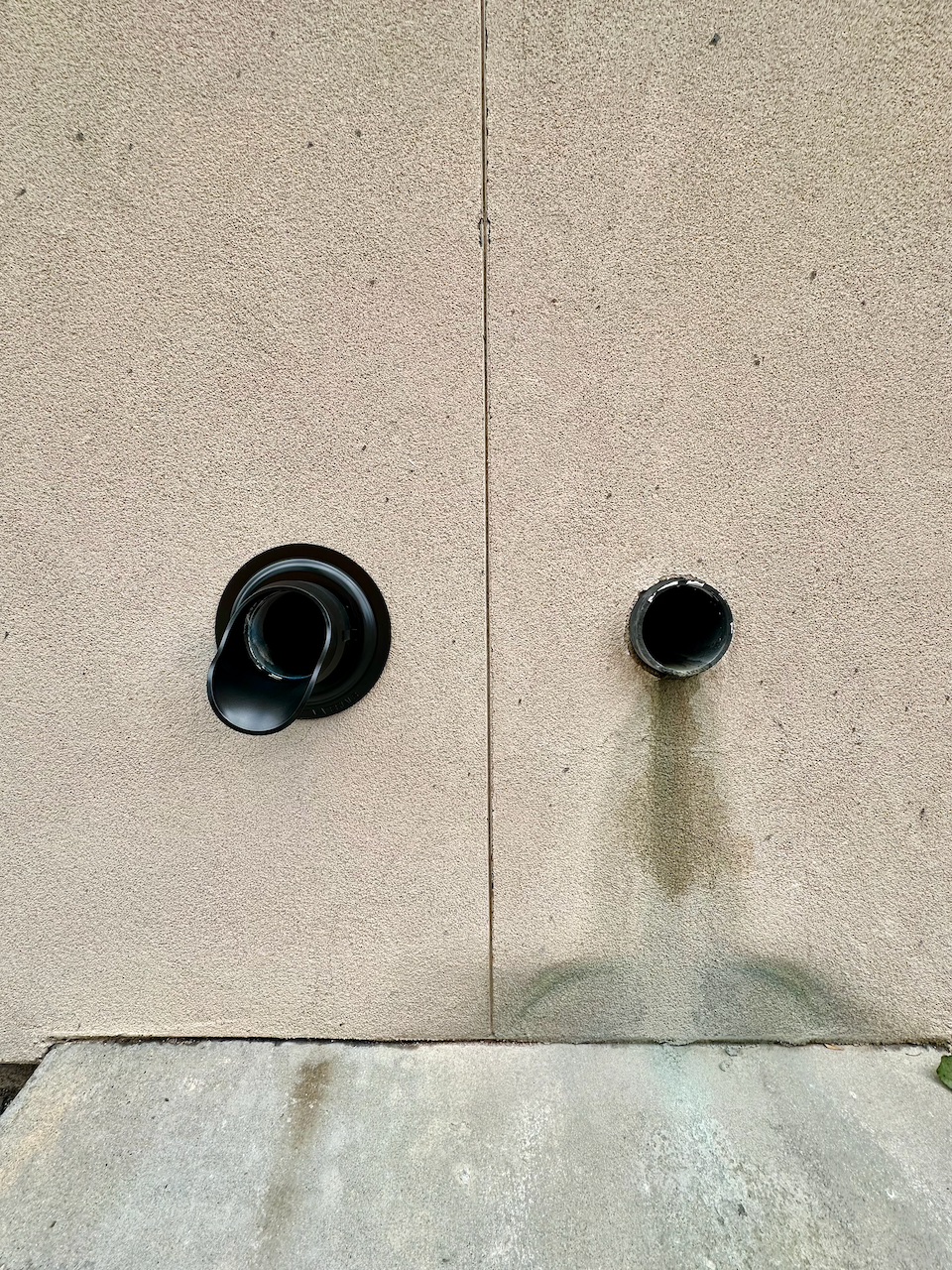

In recent years, the construction and building management industries have faced a burgeoning crisis that goes beyond the usual concerns of cost overruns and project delays: metal theft. As the prices of metals like copper, aluminum, and steel continue to climb, thieves increasingly target metal components of buildings — especially downspouts given their general ease of access. This post explores the costly impact of metal theft and presents a compelling case for switching to plastic downspouts as a secure, cost-effective alternative.

The Price of Metal Theft

Metal theft has become a significant problem globally, driven by the high resale value of common metals used in construction. The U.S. Department of Energy estimates that metal theft costs businesses and consumers $1 billion annually, a figure that includes not only the value of the stolen metals but also the cost of damages and repairs to buildings from which these metals are forcibly removed.

For property managers and developers, the repercussions are severe. A stolen metal downspout requires immediate replacement to prevent water damage, structural integrity issues, and potential liability concerns. Moreover, the replacement process often involves high costs for new materials and labor for repair and insallation (not to mention the potential for repeat thefts).

Why Plastic Downspouts Offer a Secure Alternative

Plastic PVC downspouts present a viable solution to this escalating problem. Unlike their metal counterparts, plastic downspouts do not hold any scrap value, which dramatically reduces their appeal to thieves. Here are key reasons why plastic downspouts stand out as the secure choice:

- Theft Deterrence: Plastic's lack of resale value means that your building's downspouts are less likely to be targeted by thieves. This reduces the risk of having to frequently replace stolen downspouts and save on all associated costs derived from repairing building walls, purchasing new downspout materials and the install labor.

- Cost-Effectiveness: Plastic downspouts are less expensive than their metal counterparts, not only in initial costs but also in long-term maintenance. They do not require painting or frequent replacements due to corrosion or theft.

- Ease of Installation: Given a plastic downspout decentivizes criminal from stealing the spout, there is no need for the escutcheon plate to be bolted onto the backing wall as is typically done with downspout/escutcheon plate combo's. Econocraft Materials has capitalized on this trait via our (patent-pending) self-locking escutcheon plate which locks directly onto the downspout, eliminating the need for additional hardware to drill or bolt the plate during install. This feature simplifies installation, reduces install materials/costs, and minimizes damage to the building's exterior.

- Durability and Aesthetics: Despite their practical benefits, plastic downspouts do not compromise on aesthetics or durability. They are designed to withstand harsh weather conditions and are available in various styles to match the architectural design of any building.

Conclusion

As metal prices continue to rise, so too does the frequency of metal theft. For building managers, developers, and owners, the switch to plastic downspouts isn't just a matter of choosing a cost-effective alternative; it's about securing their assets from ongoing theft and vandalism. Plastic downspouts offer a secure, economical, and practical solution that meets the needs of modern building management while ensuring that the exterior of your property remains both functional and visually appealing.

Investing in plastic downspouts could mean the difference between a secure building and one that's prone to recurring expenses. It’s time to consider making the switch and secure your investment against the rising tide of metal theft.